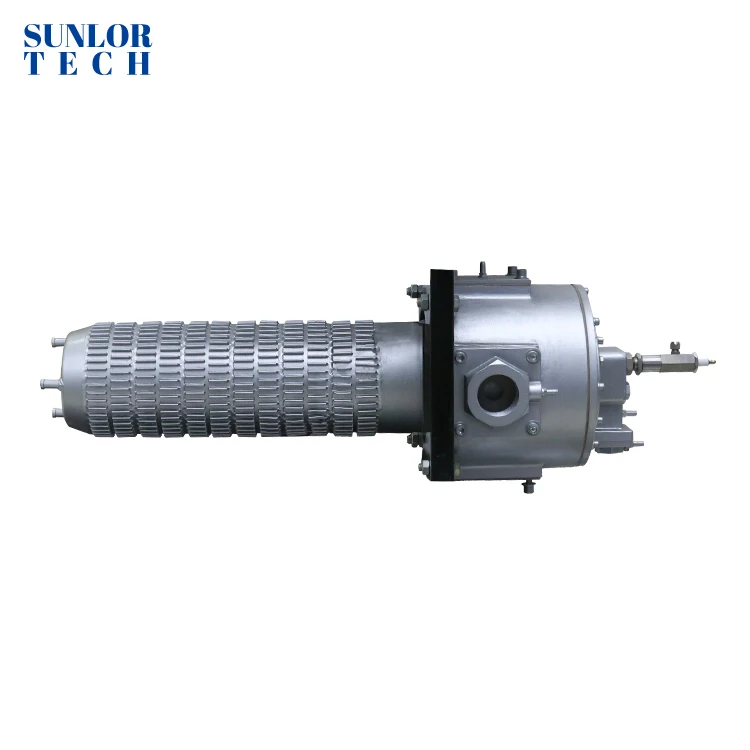

| Cases to apply A-MAX Self Preheat Nozzel/burner |

1.It includes 7 specification following power of nozzels, it's power range 12-500kW. Highest applicable furance temperature of sisic heat exchanger reaches 1300 degree highest applicable furance temperature of cast steel exchanger is 1150 gegree control means: on-off pulse control and indirect heat |

| 2. Fuel: natural gas, liquefied gas, coke oven gas, mixed gas, producer gas |

| 3. Combustion-supporting gair is preheated by use of flue gas and trrough heat xhcanger installed inside |

| 4. As the heat exchanger adopts the best graphic designing, it can get high heat exchange efficiency, high velocity when fmale is sprayed :max 120-160M/S when heating with open fire, the specially-designed fule gas injectors ensures that all fule gas be injected from the nozzle |

| 5. For direct eelctrode ingnition, flame detedtion adopts ignization or ultravioiet uv means. |

6. By use of multi-level combustion, frequent ignition is frequent and toxic substances contained in the fuel gas are at a low level, the heat exchanger adopts metals or ceramic materials and has multipie standard length. It is suggested that pulse on-off control means be adopoted, which can validy prolong duration of radiant tube and improve unformity of high furance temperature, it can also be sued for continuous control. |

7. It is used to direct-heating or indirect -heating equipment |

8. The heat exchanger is designed with the most optimal sructure and high heat exhchange efficiency that saves energy, air preheat temperature reaches 700 degree with module designing, it's flexible in use, convenient in dismantling and individualized in maintenance. the nozzel adopts pulse model that can acquire high temperature uniformity and usage life |

| 6. Self preheat nozzle that goes with heat resistance steel. carborundum radiant tube and carborundum duct is applied to products needing isloated or heating with protective atmosphere such as non-oxidation roller hearth furnace, protective atmosphere mesh furance and continuous annealing line, etc. when it is applied to radiant tube indirect heating syste,. common types of radiant tubes cover type P and Type W |

| Self prehat nozzel are ususally used in energy-conservative direct heating system by combing with smoke ejector and exhaust casing. it is primarily applied to steel, nonferrous industry and other industrial furance and combustion systems such as indoors furance, trolley furance, belt-type furance, rotary hearth furance and ceramic rollr kiln.etc |

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Gas Solenoid valve

Wind/Air Actuator valve

Manual gas and wind valve

Gas air propotional Valve

Gas regulator pressure valve

Flame detection and burner ignition controllers

Blowers

Accessories